Printing

Printing is the most popular and cost effective technique and can take the format of pad (tampo) or screen printing. Pad printing involves the use of a pad to apply the ink to the product. Screen printing applies the ink via the use of a stencil placed on a porous material screen.

FOR PLASTIC, PU AND METAL ITEMS

Screen Printing Bags

Printing is the most popular and cost effective technique. Screen printing applies the ink via the use of a stencil placed on a porous material screen.

FOR BAGS

Rotary Engraving

The principle is much the same as standard engraving but specialist machinery enables the item to be rolled as is it marked, allowing the branding to cover the circumference of the item.

FOR METAL ITEMS WITH CYLINDRICAL SHAPES

Transfer Printing

A printed image is applied to thermal paper which is then transferred to the item via a heat process. This technique is ideal for reproducing four colour process logos onto material based product.

FOR MATERIAL ITEMS SUCH AS BAGS.

Label/Doming

Self-adhesive printed label. For doming add an epoxy dome cover made of polyurethane resin; it’s durable, tough and long lasting. The label and doming process is often used to achieve four colour process logos and can be more cost effective than other printing methods, as it is the same cost regardless of the number of print colours.

DOMING FOR RECESSED ITEMS, LABELS FOR JARS AND SANITISERS

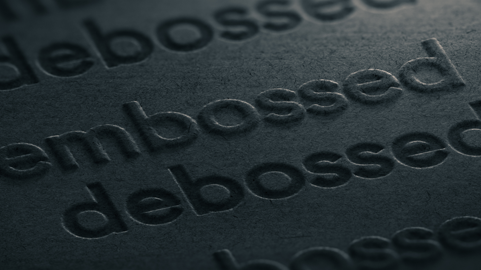

Foil Blocking

Similar to debossing (and using the same machinery), foil blocking leaves an imprint in the item, but the difference is that it can add colour to the impression. The colour is added by putting a colour foil between the dye and the product. The most popular colours to use are silver and gold.

FOR PAPER AND PU PRODUCTS

PVC

PVC (polyvinyl chloride) is a type of plastic which is easy to mould and can be produced in many colours. A bespoke mould is created incorporating a logo in various shapes and designs and is then filled with the liquid PVC and left to set and harden. Set up costs are low, allowing small order runs.

FOR PLASTIC PRODUCTS

Iron Stamping

A heated metal dye is pressed into the surface of the item which leaves behind an impression. The impression is then filled with colour.

FOR ITEMS WITH SOLID METAL SURFACES